HOD Corner:

It

gives me immense pleasure to present the July 2025 edition of our Department of

Electrical Engineering Newsletter. This month has been filled with enriching

activities that contributed to the academic growth, professional grooming, and

holistic development of our students.

Our

department organized multiple expert sessions and panel discussions that

provided valuable exposure to emerging technologies, automation, renewable

energy applications, and career opportunities in electrical engineering. These

initiatives have bridged the gap between classroom learning and industrial

practices, fostering confidence and curiosity among students.

We are

proud to celebrate the achievements of our students, be it securing placements,

excelling in academics, or winning championships in sports. Alumni interactions

further strengthened the bond between our department and its graduates, inspiring

current students with practical insights into career paths and industry

readiness.

I am

also delighted to witness our students’ active participation in cultural and

traditional celebrations such as Guru Purnima, which reflects their respect for

values alongside their pursuit of technical excellence.

I take

this opportunity to appreciate the dedicated efforts of faculty members,

student bodies, and alumni who contributed towards the success of this month’s

initiatives. Let us continue to work together with the same zeal and commitment

to nurture competent, responsible, and innovative electrical engineers.

Department Events:

Expert session on “Students to Engineers" by Mr. John Yesuraj, General Manager (R&D-Retired), CG Power and Industrial Solution Ltd, Nashik, on 25th July 2025

Expert session on “Technology Driven Solutions for Social Problems" by Mr. Prashant Bachhav, Owner, Arya Technologies, Nashik, on 23rd July 2025

An

Expert session has been arranged by IEEE On-Campus of the electrical department

on “Technology Driven Solutions for

social problems", Third Year Electrical Division: A and B students and staff of the

department on 23/07/2025.Resource Person was“Mr. Prashant Bachhav”, Owner, Arya Technologies, Nashik, India. Total No. of

Students present = 114. The expert session on Technology-Driven Solutions for

Social Problems highlighted the innovative technologies for societal problems.

The session focused on the role of modern tools such as IoT, AI, data

analytics, and renewable energy solutions in solving issues related to

healthcare, education, environmental sustainability, waste management, and

public safety. The expert shared real-life case studies and successful

technology implementations, encouraging students to think critically and

develop cost-effective, scalable solutions for community welfare. The lecture

inspired participants to leverage their technical knowledge to create impactful,

socially responsible innovations.

Expert session on “Control System Automation" by Mr. Sahebrao Salunke, Owner, Salunke Automation Ltd., Nashik, on 31st July 2025

An

Expert session has been arranged by the IEEE On-Campus of the electrical

department on “Control System Automation", Third Year Electrical Division: A students and staff of the department on

31/07/2025.Resource Person: “Mr.

Sahebrao Salunke” Owner, Salunke Automation Ltd., Nashik, India. Total No.

of Students present = 68. This lecture helped students acquire knowledge

regarding Control System Automation involving the use of sensors, controllers,

actuators, and software to automatically monitor, regulate, and control

industrial or mechanical processes with minimal human intervention. It

integrates technologies like PLCs, SCADA, and communication networks to ensure

efficiency, accuracy, and safety in operations. Control systems can be

open-loop, where there is no feedback, or closed-loop, where the system

continuously adjusts based on feedback from sensors. This automation enhances

productivity, reduces errors, and optimizes process performance across various

industries.

Panel Discussion on Scope and Career Opportunities for Electrical Engineers

On 12th July 2025, the Department of Electrical Engineering, K K Wagh

Institute of Engineering Education and Research. We were honored to host a

dynamic Panel Discussion that explored the Scope and Career Opportunities in

Electrical Engineering, featuring insights from industry experts and seasoned

professionals.

Esteemed Panel Members:

1. Mr. Sunil Tidke, Plant Head,

Mahindra Accelo

2. Mr. Prasad S P., Certified

International Supply Chain Professional (CISCP), Dubai

3. Mr. Pankaj Patil, Additional

Executive Engineer, MSETCL

4. Mr. Nitin Khatal, Technosys

Control Solutions, Nashik

5. Mr. Sachin Mishra, Global Product

Manager, ABB India Limited

The discussion was excellently

moderated by Ms. Rohini Dhikale, Third Year Student. The event offered valuable

insights into the evolving landscape of the electrical engineering

profession—from core industry roles to entrepreneurship, public sector

opportunities, and the

Expert session on “Testing of SCR & Transistors" by Mr. Sanjay Chaudhary, Director, Electronics Study Centre, Nashik, India, on 16th July 2025.

An

Expert session has been arranged by EFFECT On-Campus of the electrical

department on “Testing of SCR &

Transistors" Second Year Electrical Division: A and B students and staff of the department on 16/07/2025. The

Resource Person was“Mr. Sanjay Chaudhari", Director, Electronics Study Centre,

Nashik, India. Total No. of Students

present = 91. The expert session on Testing of SCR and Transistors provided

valuable insights into the practical aspects of semiconductor device testing.

The session covered the fundamental working principles of SCRs and transistors,

their characteristics, and various testing methods used to assess device

functionality and performance. Students gained hands-on knowledge about

identifying faulty components, using testing equipment such as multimeters and

curve tracers, and understanding real-world applications in power electronics

circuits. The lecture enhanced students' technical skills, bridging the gap

between theoretical learning and industrial testing practices.

Expert session on “Understanding Renewable Energy Technologies for Rural Communities” by Mr. Sanjay Trimbak Kawale, Technical Consultant – Solar Energy & Sustainable Technologies, 25th July 2025.

Department of Electrical Engineering,

under the Education and Energy

Awareness Program (EEAP), organized an expert lecture on “Understanding

Renewable Energy Technologies for Rural Communities” for T.Y. A and T.Y. B students on 25th July 2025. Resource Person: Mr.

Sanjay Trimbak Kawale, Technical Consultant – Solar Energy &

Sustainable Technologies

Total Number of Students Present:110.The expert lecture was designed to provide students

with a technically in-depth understanding of renewable energy technologies,

with a specific focus on rural and agricultural applications. The session

emphasized the practical design, standards, and implementation of solar

photovoltaic (PV) systems in residential and farming sectors, aligning

engineering knowledge with real-world needs and national development

priorities. Mr. Kawale elaborated on the design methodology for standalone and

grid-connected solar PV systems, including solar pump-based irrigation systems.

Key topics included selection of PV modules based on efficiency and climatic

conditions, system sizing using load analysis and solar insolation data,

inverter selection with MPPT logic, battery sizing based on load profiles and

autonomy days, and optimization of panel tilt angles to match seasonal solar

trajectories.

Expert session on "Recent Advancements in Synchronization Techniques” by Mr. Pramod Daspute, by Shri. Abhijit Borade, Deputy Executive Engineer, Mahagenco, on 29th July 2025

The session was delivered by Shri. Abhijit Borade, Deputy Executive Engineer, Mahagenco, shared valuable insights into modern synchronization practices and their relevance in today's power systems. His practical experience and technical depth greatly enriched the students' understanding of the subject.

Student Corner:

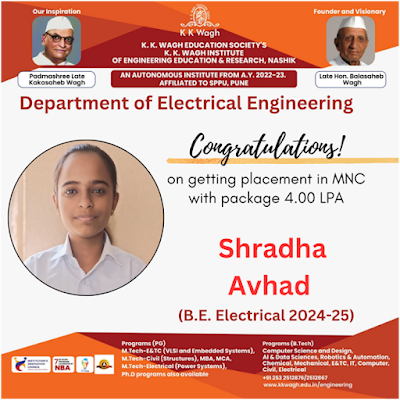

Student Placement:

The

following students are placed in various multinational companies.

Congratulations to all the students!

Placed

Students' Details (July 2025)

|

Sr. No. |

Name of the Student |

Package |

Placement Date |

| 1. |

Beldar Paras Prashant |

3.6 |

07/07/2025 |

|

2. |

SumitDevidasGhuge |

3 |

09/07/2025 |

|

3. |

Aditya Milind Patil |

2 |

21/07/2025 |

|

4. |

Mahesh Sanap |

2 |

21/07/2025 |

Honoring the Academic Excellence of Final Year Toppers (2024-25)!

We are delighted to announce

the toppers of Final Year Electrical Engineering (2024-25) from our department!

Heartiest

congratulations to all six students for their outstanding academic

achievements!

Wishing you all great

success in your future endeavors!

Alumni Interaction with Third-Year Students!

Alumni Interaction with Third Year Students

Guidance from Alumni: Empowering Final Year Students for Placements!

Celebrating Guru Purnima with Gratitude and Reverence

On 10th July 2025, the EFFECT Student Body of the Department of

Electrical Engineering celebrated the auspicious occasion of Guru Purnima by

seeking the blessings of our respected Principal, Deans, Heads of Departments,

and all faculty members.

This heartfelt gesture was led by student representatives:

Omkar Jadhav, Ankita Karanjkar, Soham Parwate,

Akanksha Khandekar, Shravani Shelke, and Atharva Bhagare, who expressed deep respect and appreciation for

the invaluable guidance of their mentors. Guru Purnima is a day to honour those

who illuminate our paths with wisdom. We are proud of our students for

upholding this tradition with sincerity and warmth.

Victory Alert!

We are proud to announce that

Team Electrical has emerged as the champion of the Karmaveer Premier League,

held on 29th July 2025!

This is a moment of immense pride and joy for all of us. The team's

dedication, teamwork, and sportsmanship truly stood out throughout the

tournament.

👏 Congratulations to all the team members for this well-deserved

victory:

🔹 Dev Pagare – Captain

🔹

Vishal Nikumbh – Vice Captain

🔹 Om

Ippar

🔹

RohitSanap

🔹

ParthWarhade

🔹

Piyush Jadhav

🔹

Tejas Wagh

🔹

AshwinDhanage

🔹

Bhagesh Ahire

🔹

Harshal Patil

🔹

ShilwanChavhan

Your energy on the field and unity off the field made this win possible.

Here's to many more victories ahead! 🥳🎉

Hyderabad Alumni Meet | 26th July 2025

Such meetings strengthen the bond between our institute and its alumni, inspiring current students and fostering new collaborations.

Student Article:

Industry Visit to Salunke Automation Private Limited

Gaikwad Harshad Sachin TE-A

(Electrical) hsgaikwad370623@kkwagh.edu.in

Company Profile:

Name of company

Founder: Mr. Sahebrao Salunke and Miss. Monal Salunke

Title: The visit to “Salunke Automation Private

Limited” Company under the Course Industry Connect ( IC )

Introduction:

Industrial

visits play a crucial role in bridging the gap between theoretical knowledge

acquired through academic curriculum and practical exposure to real-world

industrial operations.

Recognizing the importance of this experiential learning, an industrial visit

was organized for the students of Third Year (TY) as part of the Industry

Connect Course to Salunke Automation Pvt. Ltd., located at MIDC Ambad, Nashik,

on 21st April 2025.

Salunke

Automation Pvt. Ltd. is a reputed organization in the field of industrial

automation, specializing in the design, manufacturing, and testing of a wide

range of electrical panels and automation solutions. The visit was aimed at

providing students with first-hand experience of how theoretical concepts such

as electrical drives, automation systems, and control panels are practically

implemented in an industrial setting.

The visit

was meticulously coordinated by Mr. Atul Shewale and Dr. Saravanan S, who

ensured smooth execution of the plan. Students were guided through various

departments of the company where they observed the detailed processes involved

in the design, assembly, wiring, and quality testing of products such as VFD

panels, AC/DC drive panels, APFC panels, AMF panels, MCC panels, PCC panels,

PLC control RIO panels, and railway relay assemblies.

Through

this visit, students were introduced to real-time industrial challenges, safety

practices, technical standards, and quality assurance protocols, enhancing

their understanding of the practical aspects of their academic studies.

The

experience provided valuable insights into current industrial trends, new

technologies, and the importance of precision and reliability in the automation

sector.

Objectives: The

main objectives of the industrial visit were

2. To understand the complete

process involved in the manufacturing, assembly, and testing of various types

of control panels and drive systems.

3. To observe the implementation of

safety practices, quality standards, and testing protocols in the industrial

setting.

4. To familiarize students with the

latest technological advancements in the field of industrial automation.

5. To encourage students to pursue

careers and further research in automation, power systems, and industrial

electronics.

Vision: Salunke

Automation strives to provide world-class technology with utmost satisfaction to

all the clients and uphold the principles of business ethics by giving the best

services across the industry. We will be regarded as one of the best companies

in our field of work.

Mission: To

evolve as a leading Automation company, by providing unmatched quality,

products, innovations and services, in all fields of instrumentation and

automation at the most competitive prices and always surpassing the customer

expectations to keep our customers always satisfied.

Key Learnings from the Visit:

1. AC/DC Drive Panels

and VFD Panels: Students were introduced to the

working of AC and DC drive systems.

4. APFC Panels: Students

learned about Automatic Power Factor Correction (APFC) panels, which are

used to automatically improve the power factor of electrical systems by

switching capacitors in and out based on load requirements. Maintaining an

ideal power factor helps industries reduce electricity bills and penalties, and

ensures efficient energy usage.

Conclusion:

The industrial visit to Salunke

Automation Pvt. Ltd. was an immensely valuable learning experience for all

the students. It provided a practical perspective on the theoretical concepts

taught in the classroom, especially related to electrical drives, automation

systems, and control panel manufacturing. Observing the design, assembly, and

testing processes of various panels, such as VFD panels, AC/DC drive panels,

APFC panels, AMF panels, MCC panels, PCC panels, and PLC control RIO panels,

deepened the students' understanding of industry standards, safety practices,

and technological advancements. The exposure to relay interfacing modules and

railway relay assembly work highlighted the precision and quality assurance

necessary for critical applications. Overall, the visit not only enhanced

technical knowledge but also fostered an appreciation for professionalism,

teamwork, and the importance of quality control in industrial environments.

Such real-world learning opportunities are instrumental in preparing students

for their future roles as engineers and innovators in the automation and

electrical engineering sectors.

Name of company Founder: Mr. Sahebrao Salunke and Miss. Monal Salunke

Title: The visit to “Salunke Automation Private Limited” Company under the Course Industry Connect ( IC )

Introduction:

Industrial visits play a crucial role in bridging the gap between theoretical knowledge acquired through academic curriculum and practical exposure to real-world industrial operations.

Recognizing the importance of this experiential learning, an industrial visit was organized for the students of Third Year (TY) as part of the Industry Connect Course to Salunke Automation Pvt. Ltd., located at MIDC Ambad, Nashik, on 21st April 2025.

Salunke Automation Pvt. Ltd. is a reputed organization in the field of industrial automation, specializing in the design, manufacturing, and testing of a wide range of electrical panels and automation solutions. The visit was aimed at providing students with first-hand experience of how theoretical concepts such as electrical drives, automation systems, and control panels are practically implemented in an industrial setting.

The visit was meticulously coordinated by Mr. Atul Shewale and Dr. Saravanan S, who ensured smooth execution of the plan. Students were guided through various departments of the company where they observed the detailed processes involved in the design, assembly, wiring, and quality testing of products such as VFD panels, AC/DC drive panels, APFC panels, AMF panels, MCC panels, PCC panels, PLC control RIO panels, and railway relay assemblies.

Through this visit, students were introduced to real-time industrial challenges, safety practices, technical standards, and quality assurance protocols, enhancing their understanding of the practical aspects of their academic studies.

The experience provided valuable insights into current industrial trends, new technologies, and the importance of precision and reliability in the automation sector.

Objectives: The main objectives of the industrial visit were

2. To understand the complete process involved in the manufacturing, assembly, and testing of various types of control panels and drive systems.

3. To observe the implementation of safety practices, quality standards, and testing protocols in the industrial setting.

4. To familiarize students with the latest technological advancements in the field of industrial automation.

5. To encourage students to pursue careers and further research in automation, power systems, and industrial electronics.

Vision: Salunke Automation strives to provide world-class technology with utmost satisfaction to all the clients and uphold the principles of business ethics by giving the best services across the industry. We will be regarded as one of the best companies in our field of work.

Mission: To evolve as a leading Automation company, by providing unmatched quality, products, innovations and services, in all fields of instrumentation and automation at the most competitive prices and always surpassing the customer expectations to keep our customers always satisfied.

1. AC/DC Drive Panels and VFD Panels: Students were introduced to the working of AC and DC drive systems.

4. APFC Panels: Students learned about Automatic Power Factor Correction (APFC) panels, which are used to automatically improve the power factor of electrical systems by switching capacitors in and out based on load requirements. Maintaining an ideal power factor helps industries reduce electricity bills and penalties, and ensures efficient energy usage.

The industrial visit to Salunke Automation Pvt. Ltd. was an immensely valuable learning experience for all the students. It provided a practical perspective on the theoretical concepts taught in the classroom, especially related to electrical drives, automation systems, and control panel manufacturing. Observing the design, assembly, and testing processes of various panels, such as VFD panels, AC/DC drive panels, APFC panels, AMF panels, MCC panels, PCC panels, and PLC control RIO panels, deepened the students' understanding of industry standards, safety practices, and technological advancements. The exposure to relay interfacing modules and railway relay assembly work highlighted the precision and quality assurance necessary for critical applications. Overall, the visit not only enhanced technical knowledge but also fostered an appreciation for professionalism, teamwork, and the importance of quality control in industrial environments. Such real-world learning opportunities are instrumental in preparing students for their future roles as engineers and innovators in the automation and electrical engineering sectors.