Department Events

Conduction of the “Department Advisory Board Meeting”

The

department conducted the “Department

Advisory Board Meeting” with Dr. P.

B. Darji, Associate Professor, SVNIT Surat, Dr. Ujval Sonone, Sr. Manager-Technology Center-AIS, ABB India

Limited, Nashik, Shri. Pramod Haribhau

Abhang, Assistant Vice President, Popular Switchgears Private Limited,

Nashik, and all the faculty and staff members of the department. This meeting

was conducted for discussing the vision, mission, PEOs, PSOs, and the Strategic

Plan of the Department. The members provided important suggestions and inputs

on all the points.

Expert lecture on Introduction to IoT 4.0

An Expert lecture was arranged in association with the IEEE Students Chapter of the Electrical department on “Introduction to IoT 4.0” for F.Y. B.Tech (N-Div) students and staff members on 13/01/2023. The resource person was Mr. Rahul Mane, Manager, Digital Solution, Motwane Manufacturing Company Pvt. Ltd. Total No. of Students present in the session was 44. This lecture helped students to acquire knowledge application of latest trends measuring instruments.

Student Corner

Student Placement

The following

students are placed in various multinational companies in January 2023 Congratulations

to all the students!

|

Sr. No. |

Name of the Student |

Placement Date |

Batch |

|

1. |

Dhanashri Bhagawant sonawane |

03/01/2023 |

2022-23 |

|

2. |

Jayesh Raju Gulale |

03/01/2023 |

2022-23 |

|

3. |

Kunjan sanjay patil |

03/01/2023 |

2022-23 |

|

4. |

Shivanshu Pramod Bari |

03/01/2023 |

2022-23 |

|

5. |

Tanmay Santosh Patil |

03/01/2023 |

2022-23 |

|

6. |

Vaibhav

Gajanan Dhanokar |

03/01/2023 |

2022-23 |

|

7. |

Nikhil Sunil Aware |

03/01/2023 |

2022-23 |

|

8. |

Omkar Sanjay Bhange |

03/01/2023 |

2022-23 |

|

9. |

Siddhant Milind Shegaonkar |

03/01/2023 |

2022-23 |

|

10. |

Somesh Sanjay Bhosale |

03/01/2023 |

2022-23 |

|

11. |

Srushti Kiran Pawar |

03/01/2023 |

2022-23 |

|

12. |

Rushikesh Sanjay Borse |

24/01/2023 |

2022-23 |

|

13. |

Sakshi Vilas Lokhande |

24/01/2023 |

2022-23 |

|

14. |

Abhishek

Devendra Shirsole |

24/01/2023 |

2022-23 |

Project presentation organized

by Internal Quality Assurance Cell (IQAC)

Presentation of the two top scorer project groups of the

Department was arranged at the Internal Quality Assurance Cell (IQAC) of the

institute on 31/01/2023. One group is guided by Dr. R. K. Munje and the other by Prof. G. N. Jadhav. Project monitoring is done by Project

Coordinators, Dr. S. S. Dhamal and Prof. A. M. Shewale.

Visited GE Aviation, Pune for campus placement

Final year students visited “GE Aviation” Pune for campus placement on 25/01/2023 with Prof. Saravanan and Prof. Snehal Sagare. Wonderful

experience for all the students.

Congratulations

Electrical TE (A-Div) student, Rohit Rokade has

successfully completed the 16 hours of the Industry Connect program from

05/09/2021 to 17/10/2022.

The Indian Air Force has organized a special student interaction road drive for KK Wagh Students

The Indian Air Force has organized a special student

interaction road drive for K. K. Wagh students on 28th January 2023.

Highlights of interaction are as below:

(a) IAF Officials have interacted with students so that they

become aware of IAF.

(b) Guided various career opportunities available in the Air

Force Area

(c) Showcase of “Induction publicity exhibition vehicle”

(IPEV) developed specially by IAF This Air Force bus is similar to the Aircraft

Simulator and was demonstrated in the batch of 15 students and given the experience

of Aircraft. A total of 400 students participated. Event coordinators Prof P. B. Surwade and Prof. Saravanan S.

Faculty Corner

Industrial Training/Courses done by staff during January 2023

Prof. S. A Sagare and Prof. P. V. Dhole visited Advent Power

Tech Pvt.Ltd, on 5th January 2023, and interacted with Ms. Premlata

Mishra.

Prof. Ganesh N. Jadhav visited Indian Oil Corporation Ltd.

on 1st January 2023 and interacted with Mr. K. Gururaj.

Dr. R. K. Munje, Dr. S. S. Dhamal, Prof Nayana N Jangle,

Prof. S. K. Shinde, and Prof. A. M. Shewale visited Nashik Engineering Cluster

on 17th January 2023 and interacted with Mr. Manvendra Yadav, DGM

Innovation Incubation and Skill Development.

Dr. S. S. Dhamal and Prof. S. K. Shinde visited PVN

Transformer Pvt..Ltd. Ambad, on 19th January 2023 and interacted

with Mr. Parag Valmik Nikhade.

Dr. R. K. Munje, and Dr. S. S. Dhamal, visited Crompton

Craves Ltd. Nashik, on 16th January 2023 and interacted with Mr.John Yesuraj.

Faculty Publication

Ravindra Munje, Priya Rakibe, Vikrant Nichit, Anup Dudhekar, and Yogita Shewale. New Approach for Providing Adaptable Curriculum Enrichment through Teaching-Learning and Evaluation. Journal of Engineering Education Transformations (2023). Volume: 36, Issue: Special Issue 2, Pages: 425-430

School Innovation Council

Dr. R. K. Munje delivered a session on the

constitution of the School Innovation Council under the Ministry of Education's

Innovation Cell at the K. K. Wagh Universal School, Saraswati Nagar, Nashik on

10th January 2023.

Death Anniversary

Remembering Late Hon. Shri. Balasaheb Wagh on his Death

anniversary (26/01/2023).

Student Articles

Vacuum circuit breaker

Umesh

Namdev Kalyankar,

TE-Div B, (Electrical)

1. Introduction

A breaker that uses a vacuum as an arc extinction medium is

called a vacuum circuit breaker. In this circuit breaker,

the fixed and moving contacts are enclosed in a permanently sealed vacuum

interrupter. The arc is extinct as the contacts are separated in a high vacuum.

It is mainly used for medium voltage range, i.e. from 11 kV to 33 kV. The vacuum circuit breaker has

a high insulating medium for arc extinction as compared to the other circuit breaker. The pressure inside the

vacuum interrupter is approximately 10-4 torrent and at this

pressure, very few molecules are present in the interrupter. The vacuum circuit

breaker has mainly two phenomenal properties.

1) High insulating

strength: In comparison to various other insulating media used in circuit

breaker vacuum is a superior dielectric medium. It is better than all other

media except air and SF6, which are employed at high pressure.

2) When an arc is opened by moving

apart the contacts in a vacuum, an interruption occurs at the first current

zero. With the arc interruption, their dielectric strength increases up to a

rate of thousands of times as compared to other breakers.

The above two properties make the breakers more efficient, less bulky, and cheaper. Their service life is also much greater than any other circuit breaker, and almost no maintenance is required.

2. Construction

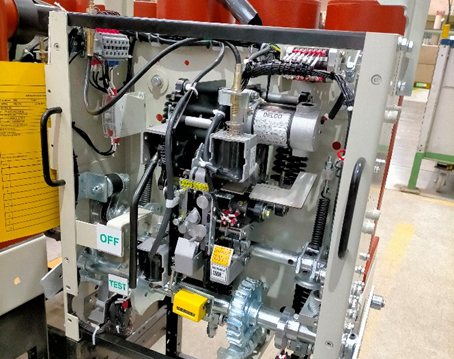

The internal view of this breaker is shown in Figure 1. (a) and (b), The circuit breaker consists of a molded insulator, housing three (3) vacuum interrupters and an operating mechanism that uses the spring stored energy system.

Figure1. (a). The circuit breaker consists of a molded insulator, b) vacuum interrupters, and an operating mechanism

3.

Operations

The motor energy-storing mechanism of the breaker is shown in Figure 2.

i) Charging of Closing

spring

When the power supply is connected to the operation circuit, energy from the motor is stored in the closing spring. When the spring changing is complete, the limit switches cut the motor supply. The indicator turns from white to yellow CHARGED condition, corning that the spring charging is complete. As the closing spring may be released by a closing signal, the limit switch closes when the closing operation terminates, causing the motor to run.

ii) Closing operation

When the closing coil is excited by

a closing signal, the closing catch is released and the closing cam is rotated

by the closing spring, which in turn rotates the main shaft. The main shaft

drives the vacuum interrupters through the wipe spring, and the circuit breaker

closes.

iii) Tripping operation

When the tripping coil is excited

by a tripping signal, the tripping catch is released, and the breaker is opened

by the opening spring

4. Working Vacuum Circuit Breaker

When the

fault occurs in the system, the contacts of the breaker are moved apart and

hence the arc is developed between them. When the current-carrying contacts are

pulled apart, the temperature of their connecting parts is very high due to

which ionization occurs. Due to the ionization, the contact space is filled

with the vapor of positive ions which is discharged from the contact material.

The density of vapor depends on the current in the arcing. Due to the decreasing mode of the current wave their rate of release of vapor fall and after the current zero, the medium regains its dielectric strength providing vapor density around the contacts reduced. Hence, the arc does not restrike again because the metal vapor is quickly removed from the contact zone.

5. Advantages of VCB

Vacuum offers the utmost insulating strength. So, it has extremely superior arc quenching properties than any other medium.

The vacuum circuit breaker has a long life.

Unlike Oil Circuit Breaker (OCB)

or air blast Circuit Breaker (ABCB), the explosion of a VCB is avoided. This

enhances the safety of the operating personnel.

No fire hazard

The vacuum CB is fast in

operation so ideal for fault clearing. VCB is suitable for repeated operations.

Vacuum circuit breakers are

almost maintenance-free.

No exhaust of gas to the

atmosphere and Noiseless operation.

6. Disadvantages of VCB

The main disadvantage of

VCB is that it is uneconomical at voltages exceeding 38 kV.

The cost of the breaker

becomes excessive at higher voltages. This is because at high voltages (above

38 kV) more than two numbers of the circuit breaker are required to be

connected in series.

Moreover, VCB production is

uneconomical if produced in small quantities.

7. Applications of Vacuum Circuit Breaker

The vacuum circuit breaker is today recognized as the most reliable current interruption technology for medium voltage switchgear. It requires minimum maintenance compared to other circuit breaker technologies. The technology is mainly suitable for the mainly medium-voltage application. Higher voltage vacuum technology has been developed, but it is not commercially feasible. Vacuum circuit breakers are used in metal-clad Switchgear and also in porcelain-housed circuit breakers.

Power Transformer

Roshan

Ramesh Bodke TE-Div B, (Electrical)

Bodkeroshan632@gmail.com

1.

What are Power Transformers?

A

power transformer is a mere classification of transformers with a voltage range

varying between 33 kV-400 kV and a rating above 200 MVA. The voltage ratings of

power transformers available in the market include 400 kV, 200 kV, 110 kV, 66

kV, and 33 kV. The other types of transformers include distribution (230 V-1kV)

and instrument transformers.

2. Common Types of Transformer Protection

Faraday’s

Law of Electromagnetic Induction

Faraday’s

law states that when a closed loop is brought near a fluctuating magnetic

field, an electromotive force (emf) will be induced across it.

Power

transformers are electrical instruments used in transmitting electrical power

from one circuit to another without changing the frequency. They operate by the

principle of electromagnetic induction. They are used in transmitting

electrical power between generators and distribution primary circuits. Power

transformers are used to step up or step down the voltage in distribution

networks. Since they have no rotating or moving parts, these instruments are

considered static devices. These instruments work based on an alternating

current (AC) electrical system.

Overheating protection

Overcurrent protection

Differential Protection of Transformer

Earth Fault Protection (Restricted)

Buchholz (Gas Detection) Relay

Over-fluxing protection

Operating Principle of Power Transformers

The efficiency of the power transformer has very

high and works at its full efficiency.

AC passes through the primary winding, which creates a

varying magnetic flux.

The magnetic field that results strikes the second winding and generates an AC voltage in that winding via electromagnetic induction

Figure.1. Transformer Working Principle

3. Stepping Voltages Up or Down

The total voltage in a winding is equal to the voltage

per turn of the coil multiplied by the number of turns. Since the voltage per

turn of the primary and secondary windings are the same, the induced voltage in

the secondary winding can be related to the input voltage on the primary

winding.

This relationship is expressed by the equation:

Vs = Vp/Np x Ns

Where V represents the total voltage in the winding, N

represents the number of turns of a winding, and the subscripts p and s refer

to the primary and secondary windings, respectively. The ratio of the number of

turns in the secondary winding to that of the primary winding (Ns/Np) is called

the turns ratio. If the number of turns in the secondary winding is fewer than

the number of turns in the primary winding, the voltage output is lower than

the input voltage (step-down transformer). On the other hand, if the number of

turns in the secondary winding is more than the number of turns in the primary

winding, the voltage output is higher than the input voltage (step-up

transformer). Since energy is conserved, the relationship between the

alternating current in the primary and secondary windings is represented by the

below equation:

Vp Ip = Vs Is

where I

represents the current.

Ratio of transformer:

N2/N1=V2/V1=I1/I2

Grounding use in power transformer:

Grounding transformers are typically used to provide a

relatively low-impedance path to the ground, thereby maintaining the system

neutral at or near ground potential. Limit the magnitude of transient overvoltages

when restriking ground faults occur. Provide a source of ground fault current

during line-to-ground faults. This is Reactor grounding.

Figure.2. Transformer Working Model

3.1.

Transformer Losses

Copper Loss

Copper

losses, sometimes called resistive or I2R losses, are the energy losses caused

by the electrical resistance of the windings to current flow. The electrical

resistance of material measures the opposition to the current flow; it depends

on the length, nature, cross-sectional area, and temperature of the material.

Copper losses are also influenced by the amount of current flowing through the

circuit. Copper losses are quantified by calculating the value of I2R.

Hysteresis Loss

Hysteresis

losses are caused by the friction encountered by the ferromagnetic molecules in

the core due to magnetization and demagnetization, as the magnetizing force

flows in forward and reverse directions. The internal friction developed caused

heat to develop within the transformer.

Eddy Current Loss

Eddy

current is produced in the core’s cross-section as a result of the fluctuating

magnetic field. It is minimized by laminating thin metal sheets (laminas)

together to construct the transformer core. The laminas are insulated by a

special coating. Through lamination, the eddy current is produced and flows

separately in all laminas, and the path for the eddy current is drastically

reduced.

4. Summary

Power transformers are static electrical

instruments used in transmitting electrical power from one circuit to another

without varying the frequency. They have a voltage range varying between

33kV-400kV.

The principle behind the design and operation of

power transformers is based on Faraday’s law of electromagnetic induction.

The main components of power transformers are

primary winding, secondary winding, and core. The relationship between the

voltage and number of turns in the primary and secondary windings are related

by the equation: Vs = Vp/Np x Ns. This relationship is used in stepping up or

down voltages.

The other components of power transformers include

insulating materials, tap changers, bushings, transformer tanks, conservators,

breathers, cooling systems, explosion vents, and Buchholz relays.

Power transformers can be classified based on core

and winding construction, turn ratio, phases, and core material.

No comments:

Post a Comment