Department Events

Expert lecture on “Importance of Professional Association for Career Development” on 25/09/2023

Department of Electrical

Engineering in Association with IET On-Campus Organizes Expert Lecture on “Importance of Professional Association for Career

Development” for TE (A and B) students and staff of the department

on 25/9/2023: Resource Person: Mr. Amitabh

Sinha, Co-founder & Chief Strategy Officer, Founder at Dcy phr. Total no. of Students present = 142. In this session, the students participating in the regional

round of the IET India Scholarship Award were felicitated with the hands of Mr.

Amitabh Sinha. The Participating students also shared their views and

experiences of participating in this Award Competition.

Expert lecture on “Artificial Intelligence-Opportunities for Future Engineers” on 27/09/2023

Department of Electrical

Engineering in Association with IET On-Campus Organizes Expert Lecture on “Artificial

Intelligence- Opportunities for Future Engineers” for BE (A and B) students and staff of the department

on 27/9/2023: Resource Person: Mr. Amitabh

Sinha, Co-founder & Chief Strategy Officer, Founder at Dcyphr. Total No. of Students present = 68. The

lecture helped students to understand the importance of artificial

intelligence, what the basics of AI are and how to grab the opportunity in AI

for the job. The expert also discussed the artificial intelligence theory and

trends in the industry of artificial intelligence.

Expert Lecture on “Guidance for Competitive Exam” on 15/09/2023

Electrical

Department in Association with EFFECT Student Body has organized an Expert

Lecture on “Guidance for Competitive Exam” for TE Electrical Division: A and B students and staff of the

department on 15/9/2023: Resource Person: Mr. Saurabh Sonawane, Educator-In

chief at Unacademy. Total No. of Students present = 90. This lecture helped students to understand the pattern of

competitive exams, how to crack the exam and the importance of competitive exams

and job opportunities in the government sector.

Department Advisory Board Meeting on 18/09/2023

The department conducted the “Department Advisory Board Meeting” on

18th September 2023 in the presence of Hon. Members and all the faculty

members.

Expert Lecture on “Power Transformer” on 23/09/2023

The department conducted an expert session of Mr. Pankaj Patil (Additional Executive

Engineer MSETCL) on 'Power Transformer'

on 23/09/2023 as a part of the course delivery by the industry expert under

Autonomy. Total No. of Students present = 58.

Certificate Course on ‘Control Panel Design’ on 14/09/2023

The department has conducted the Certificate Course on

‘Control Panel Design’ for TE and BE

students. Total No. of Students participated

= 45.

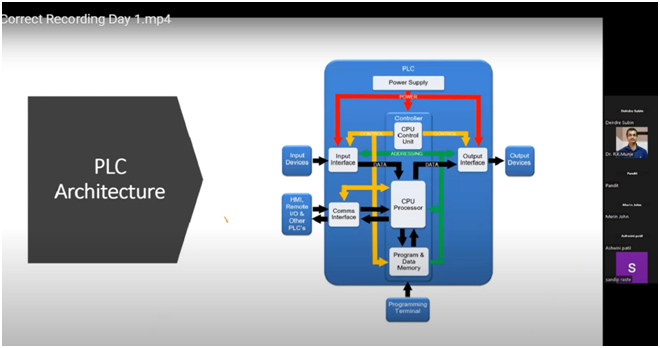

Certificate Course on ‘PLC and SCADA’ on 14/09/2023

The Department has conducted the Certificate Course on

‘PLC and SCADA’ for BE (Div B) students.

Student Corner

Student Placement

The following

students are placed in various multinational companies. Congratulations to all

the students!

Placed Students Details (September - 2023)

|

Sr. No. |

Name of the Student |

Placement Date |

|

1. |

Shewale Sanjana Bhagwan

|

09/12/2023 |

|

2. |

Sakshi Raosaheb Patil |

09/12/2023 |

Congratulations!

ABB Digi Connect 2023 Competition

ABB

Company organized the ABB Digi Connect

2023 Competition for engineering colleges. Various colleges participated

in this event. K. K. Wagh team won first prize in the ABB Digi Connect 2023

Competition. The student team members of Sakshi Girase (Electrical), Tejaswini

Rajput (R&A), Prathamesh Gadilohar (IT), Anush Devadiga (E&T), and

Yash Mahale (CSE) participated from the college. Team College Coordinator, Prof.

Saravanan S. Congratulations to all of them!

Congratulations!

On Teachers Day, Dr.

S. S. Dhamal (30 years), Dr. R. K.

Munje (10 years), Prof. J. D. Patil

(20 years) and Mrs. Shubhada Borade

(30 years) are felicitated with the hands of Dr. Vinayak Govilkar for completing the long service in the K. K.

Wagh Institute of Engineering Education and Research. Congratulations!

Industry collaboration

Industry visits by the department faculty members to Hyosung India Pvt. Ltd., Pune to

interact with Alumni and Industry professionals for collaboration on 13th

September 2023. The visit was attended by Prof. Saravanan S along

with Dr. P. J. Pawar (HOD, Robotics and Automation), Dr. P. K.

Shahabadkar (T&P Officer) and Prof. Gokul Jadhav.

Congratulations!

On Engineers Day, Prof.

Dr. Munje and Prof. Saravanan

are felicitated for writing and publishing research papers in peer-reviewed

journals and Prof. Dr. Abhishek is felicitated for completing the PhD

from NIT. Felicitation was done with the hands of Hon. Shri. Narendra Goliya in the presence of Principal Dr. Keshav Nandurkar.

Temperature

rise test and analysis of high current switchgear in the distribution system

Sayeed Hussain Naik

TE-A-Electrical Engineering

syeednaik@gmail.com

Abstract

As the load of the power system continues to increase, the capacity of the switchgear climbs, resulting in the overheating problems becoming more serious. To realize the monitoring of the temperature of the switchgear, the authors need to conduct a thorough analysis of the temperature rise principle of the switchgear first. To get the detailed temperature distribution in the switchgear, a series of temperature rise tests were carried out based on the KYN28A-12(Z) overhead line switchgear and the data were analyzed and compared in detail to summaries the factors that affect the temperature distribution in the switchgear.

1. Introduction

In recent years, the increasing power load has brought new challenges to the stable operation of switchgear. The resistance of switchgear grows with the operation, resulting in overheating in switchgear, which leads to power failure or even an explosion accident [1, 2]. References [1–4] analyzed the reasons for overheating as well as abnormal heating of the switchgear. Reference [5] dealt with the problems existing in the KYN28A-12 kV/4000 A switchgear and improved its structure. The improved performance was analyzed through simulation. Reference [6] has carried out a detailed simulation of the thermal field and the airflow field in the switchgear. Reference [7] introduced an advanced temperature measurement technology and a practical switchgear temperature warning system. However, there is little research on the rate of temperature rise and regular pattern of temperature distribution of switchgear.

2. Temperature rise tests of the switchgear

In order to get the detailed temperature distribution in the switchgear, we chose a KYN28A-12(Z) overhead line switchgear and conducted a series of temperature rise tests. 2.1 Equipment used in the temperature rise test In the tests, the KYN28A-12(Z) overhead line switchgear is shown in Fig. 1, in which A is the bus room, B is the instrument room, C is the circuit breaker room, and D is the overhead line room. The main heating points in the switchgear are located on the contact surfaces of the buses and branches in the bus room and the surfaces between the fixed contacts and the moving contacts in the circuit breaker room. The switchgear seals well because of meeting the requirement of arcing. There are three fans installed at the top of the bus room, as well as two fans installed at the top of the circuit breaker room. The power of each fan is 65 W. Two blowers are installed below the circuit breaker room, one of which is 270 W and the other is 70 W.

2.2 Positions of Temperature Sensors

Considering that the contact resistance of the contact surfaces is far greater than the resistance of the metal itself, we will place more platinum resistance temperature sensors at the main heating points as mentioned above. In the bus room, the sensors are placed in the following positions: the outlet of the fixed contact box, branches, and contact surfaces of the buses and branches. In the circuit breaker room, the sensors are placed in the following positions: outside top, bellow, left and right of all plum contact, inside top, bellow, left and right of phase B upper plum contact, outside top and left of the breaker arm, inside of the breaker arm, fixed contacts, the contact surfaces of the fixed contacts and branches.

2.3 Contents of temperature rise tests.

To

obtain more data, we set up different test conditions to simulate various

situations that may occur in the actual operation of the switchgear.

Temperature data is collected by the temperature monitoring software per

minute. The following are the contents of temperature rise tests.

(I)

Set the input current of three phases to 4400 A with the ventilation equipment

off during the test. The resistance of phase A is 23 μΩ, phase B is 23 μΩ, and

phase C is 22 μΩ.

3. Comparison and analysis of data

After a series of temperature rise tests, we have obtained a lot of data. In the following sections, we conduct a detailed analysis of the data and reach conclusions.

3.1 Comparison of temperature rise at the same positions of different phases

We chose the data from test 1 and test 5 to compare. The temperature rise of the outside top of the plum contact represents the temperature rise of the whole plum contact. (The following data are the same.) Fig. 2 shows the comparison of the temperature rises of the three-phase lower plum contacts in test 1. Fig. 3 shows the comparison of the temperature rises of the three-phase lower plum contacts in test 5.

Based on Figs. 2 and 3, it can be concluded that the temperature rise values at the same positions of different phases are basically the same when the ventilation equipment is off. However, the values change after turning on the ventilation equipment, because the speed of air changes sharply, which influences the temperature rise values.

Fig. 2 Comparison of the temperaturerises of the three-phase lower plum contacts in test 1

Fig. 3 Comparison of the temperature rises of the three-phase lower plum contacts in test 5

3.2 Comparison of temperature rise at different positions of the same phase

We

chose the data from test 5 to compare. The temperature rise of the outside top

of the breaker arm represents the temperature rise of the outside of the

breaker arm. (The following data are the same.) As shown in Fig. 4.

According to Fig. 4, we find that the temperature rise inside the breaker arm is the highest, followed by the outside of the breaker arm, the plum contact, the fixed contact, the contact surface of the fixed contact and branch, the outlet of the fixed contact box, the branch and the contact surface of bus and branch. The temperature rise has a great relationship with the speed of the surrounding airflow, and there is no significant difference in the temperature rise between two points not far from each other on the copper bus. This is the gradient of temperature distribution when the switchgear operates normally.

Fig. 4 Comparison of the temperature rises of phase C upper plum contact and the nearby positions in test 5

3.3 Comparison of temperature rise at different positions of the same plum contact

We

chose the data from test 1 and test 5 to compare. Fig. 5 shows the comparison

of temperature rise at different positions of the same plum contact in test 1.

Fig. 6 shows the comparison of temperature rise at different positions of the

same plum contact in test 5. According to Figs. 5 and 6, we see that when the

ventilation equipment is off, the temperature rise in the four directions

inside of the plum contact of phase B is basically the same, while the

temperature rise in the four directions on the outside is slightly different.

When the ventilation equipment is turned on, although the temperature rise

values vary obviously, it can still be ruled that the temperature rise inside

is higher than the same position on the outside.

Fig. 5 Comparison of temperature rise at

different positions of the same plum contact in test 1

Fig. 6 Comparison of temperature rise at

different positions of the same plum contact in test 5.

Moreover,

the Figs. 5 and 6 also prove that there is a difference in the temperature rise

value of each position of the plum contact when the ventilation equipment is

off. This is due to the complex equipment in the circuit breaker, causing the

speeds of air flow at different positions to be different.

3.4 Comparison of temperature rise in different input currents

We

choose the data of test 1, test 2, test 3 and test 4 to compare. The comparison

of temperature rise of phase C upper plum contact in different input currents

is shown in Fig. 7. According to Fig. 7, we find that the rates and stability

values of temperature rise differ significantly in different input currents. By

comparing the regular pattern of temperature rise in different input currents,

we can obtain the differences in the temperature distribution gradient.

Fig. 7 Comparison of temperature rise of

phase C upper plum contact in different input currents.

According to Fig. 7, we find that the rates and stability values of temperature rise differ significantly in different input currents. By comparing the regular pattern of temperature rise in different input currents, we can obtain the differences in the temperature distribution gradient.

3.5 Effect of ventilation equipment on temperature rise

We

choose the data of test 1, test 2, test 5 and test 6 to compare the temperature

rise of phase C upper plum contact, which is shown in Fig. 8. From Fig. 8, we

can see that the ventilation equipment has an effect on the regular pattern and

rate of temperature increases, and the temperature rise value is stabilized

quicker after the ventilation equipment is turned on.

Fig. 8 Comparison of temperature rise of phase C upper plum contact with the ventilation equipment on or off.

3.6 Effect of unbalanced current on temperature rise

We

choose the data of test 5, test 7 and test 8 to compare the temperature rise of

phase C lower plum contact, which is shown in Fig. 9. According to Fig. 9, it

can be seen that when the input current of one phase is missing, the heating of

switchgear is reduced, and the rate of temperature rise and regular pattern of

temperature distribution have certain changes.

Fig. 9

Comparison of temperature rise of phase C upper plum contact in

unbalanced current.

According

to Fig. 9, it can be seen that when the input current of one phase is missing,

the heating of switchgear is reduced, and the rate of temperature rise and

regular pattern of temperature distribution have certain changes.

4 Conclusions

This

article carries a series of temperature rise tests based on KYN28A-12(Z)

overhead line switchgear, compares and analyzes the data obtained, and reaches

the following conclusions.

(i)

The ventilation equipment has an obvious impact on the rate of temperature rise

and regular pattern of temperature distribution of switchgear.

(ii)

The different input current has an obvious impact on the rate of temperature

rise and regular pattern of temperature distribution of switchgear.

(iii)

The unbalanced current has a certain impact on the rate of temperature rise and

regular pattern of temperature distribution of switchgear.